Cartridge Heater

Get High-Quality Cartridge Heaters

Patel Heaters & Control Pvt. Ltd. is a leading manufacturer of cartridge heaters. We have designed high-quality cartridge heaters to deliver accurate and precise localized heat that is focused enough to satisfy the requirements of a wide variety of production applications. These cartridge heaters are made smaller to facilitate ease of installation. Our range of cartridge heaters includes a variety of tiny sizes with low-watt or high-watt density options. Furthermore, as one of the leading Cartridge Heater Manufacturers in India, we offer custom-made heaters with a certain watt density based on the specifications of the application.

For Your Service

(+91) 992-582-2226

Features Of Our Product

- Lead wire and internal thermocouples are available

- Provided with fittings and flanges

- Outstanding performance

- Long lifespan

- Various configurations and constructions are available

- Meets international performance standards

Applications

- Packaging equipment

- Plastic processing devices

- Labeling machines

- Gas and liquid heating

- Hot stamping

- Food processing

- Shoe manufacturing

Know More

We Are The Leading Cartridge Heater Suppliers In India

Cartridge heaters are most commonly used to heat metal objects that have been drilled.

Being a reliable manufacturer and supplier, we have produced cartridge heaters with a specific characteristic that allows for enhanced heat transfer at a very consistent and uniform temperature. As a result, these industrial heaters are the best choice for a variety of applications. Our heaters are meticulously crafted from high-quality materials, allowing them to operate for an extended period. Our staff thoroughly inspect all heaters before delivering them to our customers. If you have any further questions or wish to purchase this product, please contact us.

Ordering Info. Required

- Diameter

- Length required

- Voltage and wattage require

- Type of termination

- Drawing or photo if necessary

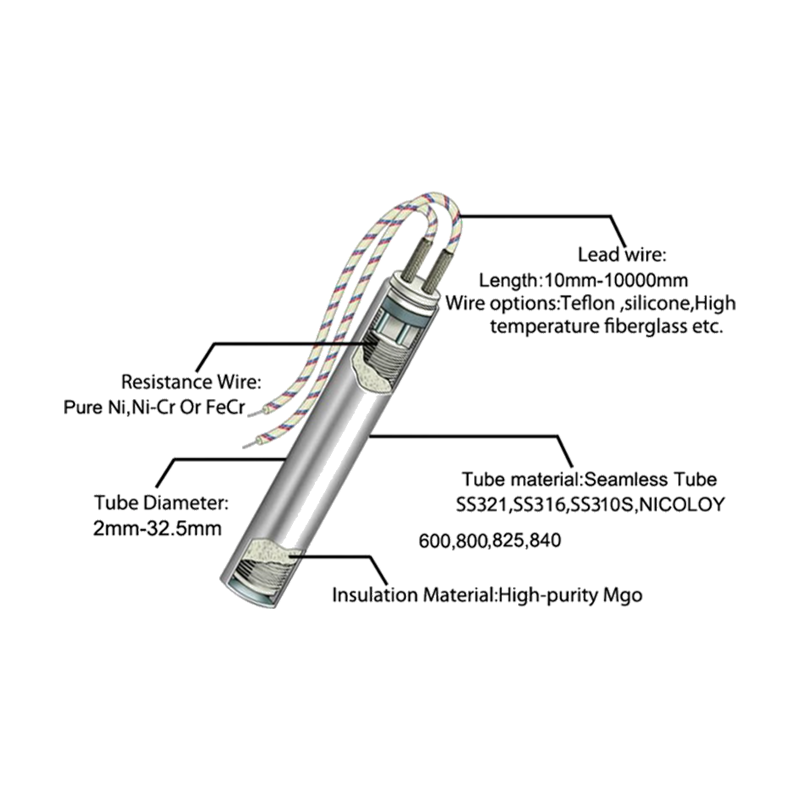

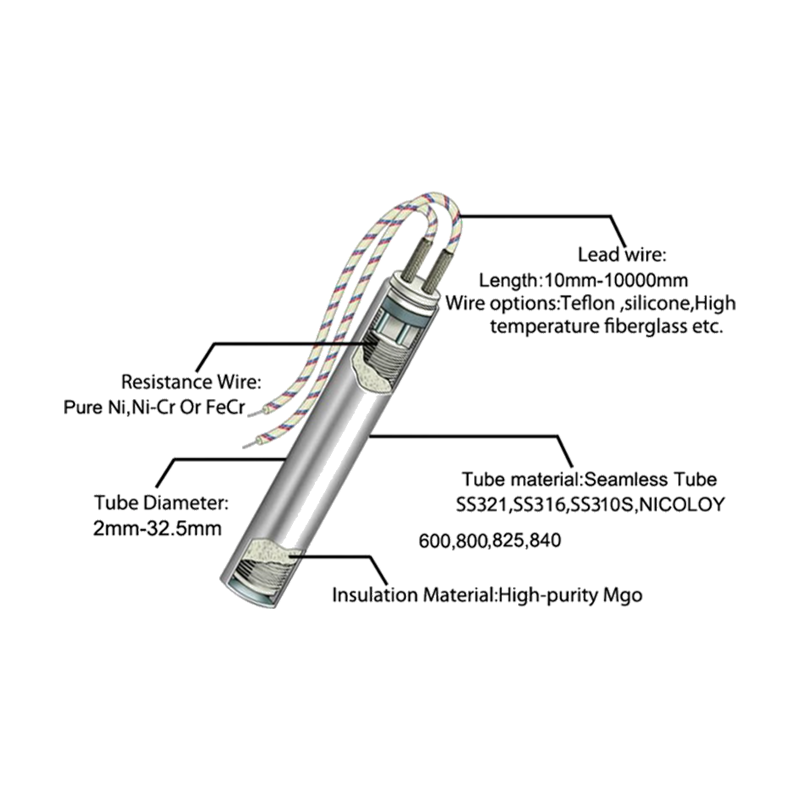

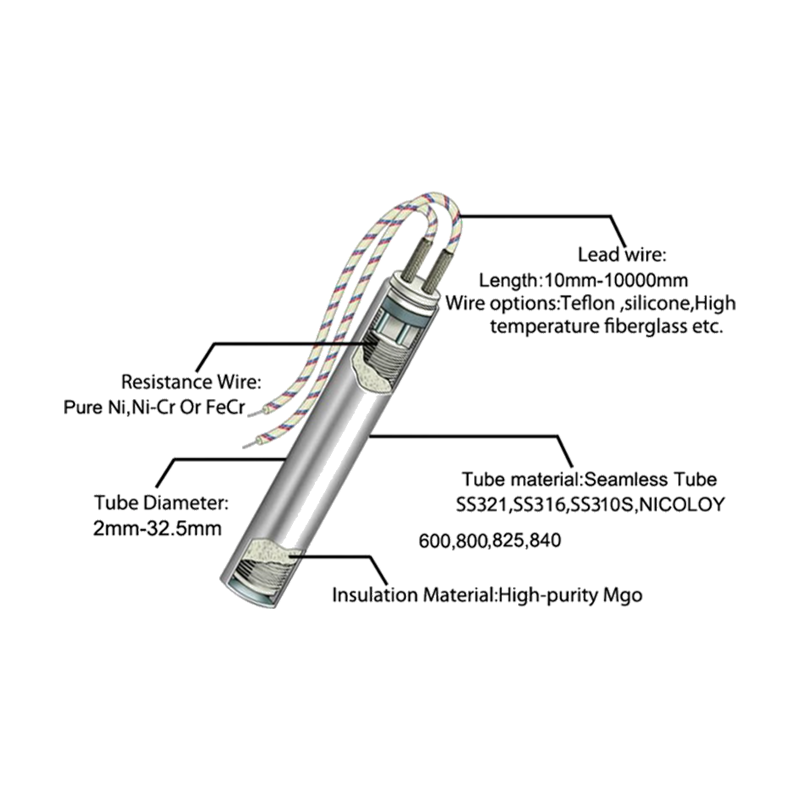

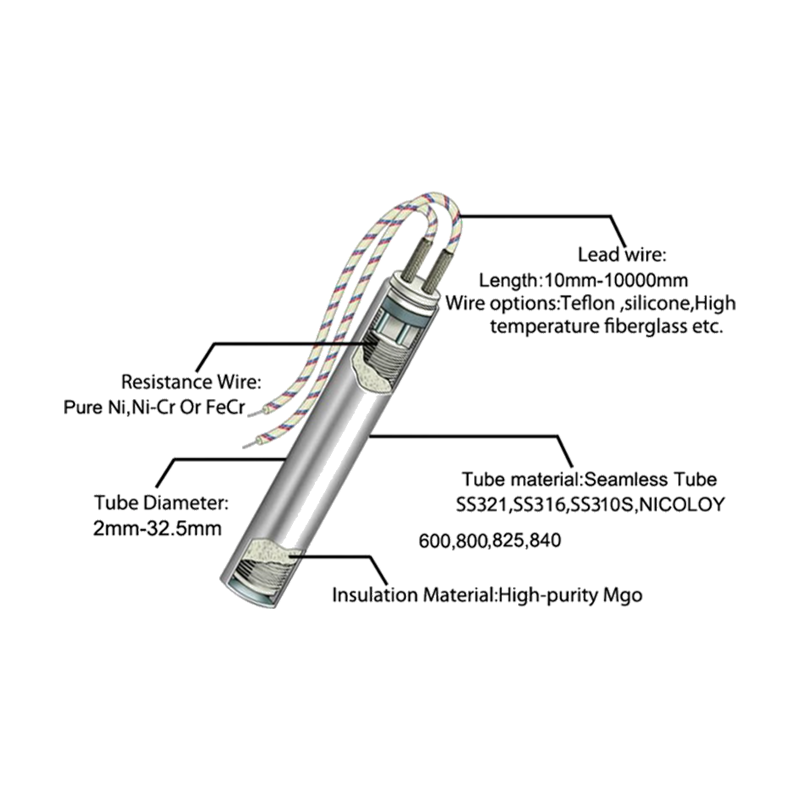

Technical Data

- Helically coiled 80/20 Nickel Chrome or Kenthal resistance wire.

- It is filled with high-purity Magnesium Oxide (MgO).

- Can be manufactured in a variety of diameters to meet specific needs.

- Maximum watt density up to 50 watts per centimeter.

GET MORE INFORMATION

We have high standards and are proud of all we do.

Crimped-On Leads

The MGT (450°C) leads are joined to solid nickel pins by a high-temperature double crimp. This structure is recommended for high-temperature applications. Because of the solid nickel pins, this construction is not suggested for applications requiring movement or flexing, or for steep bends next to the heater exit.

Swaged in Leads

Internally linked and swaged in high-temperature MGT (450°C) wire. This structure is suitable for applications where the leads must be bent at the heater’s exit point and where slight flexing may occur. We recommend metal braid or armor cable for applications with continuous or severe movement.

Stainless Steel Braid

MGT (450°C) wire is internally linked and swaged in place, together with stainless steel braid. This construction protects against scratches and sharp edges. This is an extremely sturdy structure with full-length flexibility. This structure is suitable for flexing applications where the leads must pass through metal apertures or be routed along metal components.

Stainless Steel Armoured Cable (Hose)

High-temperature MGT (450°C) wire is internally linked and swaged in place, together with a stainless steel hose. This structure is suitable for applications where the leads are likely to get scratched or damaged. This is the most powerful lead protection available, and it performs well in moving or flexing applications.

Right Angle Fibreglass Leads

High-temperature MGT (450°C) leads exit at a right angle to the sheath. When space is restricted, this construction provides a compact design. This structure is not advised in areas prone to abrasion or bending.

Right Angle Stainless Steel Braid

Stainless steel braid over 450°C MGT wire exiting at the right angle to the sheath. This structure is suitable for flexing applications where the leads must pass through metal holes or go along metal components. This construction is highly preferable when space is restricted and standard leads cannot be bent.

Right Angel Stainless Steel Armour (Hose)

Stainless steel hose over high-temperature MGT (450°C) wire exiting at the right angle to the sheath. This is the most powerful lead protection available for use in applications with high abrasion. These leads have excellent flexibility and are ideal for moving or flexing applications.

| Heater Diameter | Minimum Unheated Length |

|---|---|

| 1/8“ | Not Available |

| 1/4“ | 1″ |

| 5/16“ | 11/2“ |

| 3/8“ | 11/2“ |

| 1/2“ | 11/2“ |

| 5/8“ | 19/16“ |

| 3/4“ | 17/8“ |

| 15/16“ | 17/8“ |

| 1″ | 17/8“ |

OUR SPECIALITY

FITTINGS & FLANGES

Mounting Flanges

Mounting flanges are advised for applications where vibration or movement could cause the heater to tumble out of its hole. Stainless steel flanges come in a wide range of diameters and designs. The typical flange is circular and has two mounting holes. The flange would be 1 1/2′′ in diameter for heaters 5/8′′ and below than this. The standard flange diameter for larger diameter heaters is 2.00′′.

| Heater Diameter | NPT Size | X Dimension | Y Dimension | Y1 Dimension |

|---|---|---|---|---|

| 1/4“ | 1/8-27 | 3/8“ | 3/16“ | 1/4“ |

| 3/8“ | 1/4-18 | 1/2“ | 3/16“ | 1/4“ |

| 1/2“ | 3/8-18 | 9/16“ | 1/4“ | 1/4“ |

| 5/8“ | 1/2-14 | 5/8“ | 1/4“ | 5/16“ |

| 3/4“ | 3/4-14 | 3/4“ | 1/4“ | 3/8“ |

| 7/8“ | 1-111/2 | 3/4“ | 1/4“ | 3/8“ |

| 1″ | 1-111/2 | 3/4“ | 1/4“ | 3/8“ |

| 11/8“ | 11/4-111/2 | 7/8“ | 5/16“ | 1/2“ |

Our main Process

OPTIONAL CONSTRUCTIONS

Double Ended Terminals

These terminations are appropriate for applications that require wiring from both ends. These leads must have a minimum cold section of 1′′.

Screw Terminals

Threaded stud terminals are provided complete with high-temperature nuts and washers. The standard screw size is #8-32. Available in 5/8′′, 3/4′′, 1′′, 16 mm, and 20mm diameters heaters.

Teflon End Seal

A Teflon plug and Teflon leads are swaged in place. The construction is oil and water-resistant up to 250°C/480°F. At the lead end, there is a minimum of 1.00′′ unheated length. If the watt density or operating temperature is high, longer cold portions may be required.

Available Terminations

- Solid nickel pins made of solid nickel

- Leadwires

- Threaded studs

Terminal Boxes

Terminal boxes are securely attached to the heater sheath to provide exceptional protection in a range of conditions.

Available Boxes

- General-purpose sheet metal

- Moisture-proof

- Cast aluminum explosion-resistant

Know More

INTERNAL THERMOCOUPLES

Internal thermocouples are incorporated within the heater assembly to monitor the internal or sheath temperatures. These are useful as high-capacity devices or in applications where space is limited. The power and sensor leads exit the sheath jointly and can be customized with various lead safeguards. On smaller-diameter heaters, not all thermocouple configurations are accessible. Type J and K calibrations are standard for the shown structures.

Grounded at Disc End

The thermocouple joint is grounded to the heater’s disc end. This structure is frequently utilized in hot runner applications. The disc end can be silver soldered and ground flat. When fitted into a flat-end blind hole, this will ensure good contact.

Ungrounded at Disc End

The thermocouple junction is ungrounded and is placed directly behind the disc end. This will provide a reference temperature of the component being heated.

Grounded at Centre

The thermocouple joint is connected or grounded to the sheath across the length of the heater. The typical location is in the center of the heater, however it can be placed anywhere along the sheath’s length. This design enables a speedy response.

Ungrounded at Centre

The thermocouple conjunction is ungrounded and centered in the sheath’s diameter. The most typical location is in the center of the heater, however it can be anywhere along the sheath’s length. In air or vacuum applications, this is typically employed as a high limit.

Patel Heaters & Control Pvt. Ltd.

Connect With Us Today!

Mobile

+91-987960 7852, +91-99258 22223/ 99789 16315

Address

901/5/5, Gidc, Makarpura Vadodara Gujarat India -390010

Landline no

+91-99258 22227,

+91-99258 22229

E mail

sales@patelheaters.com

Fill The Form To Connect With Us