Tubular Heater

Patel Heater & Control Pvt Ltd is proud to present highly advanced Tubular Heaters in India.

We develop high performing Tubular Heaters that are designed at our in house facility keeping in mind the requirements of our customers and meeting them using latest technology solutions. Made from superior quality raw materials, our Tubular Heaters have sturdy construction and unique design that makes them perform better compared to its competitors.

For Your Service

(+91) 992-582-2226

Features Of Our Product

- Available in wide variety of ratings, shapes and sizes

- Made from superior quality raw materials

- Can be transformed to fit any construction design

- Advanced Technology

Applications

- Forced air heating

- Comfort radiant heaters

- Combination radiant and convection heater for ovens and dryers

- Welded, brazed or clamped to tanks and pipes

- Hot runner molds

- Direct immersion in liquids

- Thermal forming machines

Know More

Enhance Your Industrial Processes With Innovative Tubular Heater

Ordering Info. Required

- Volt & Wattage Require

- Dia & length of the heater Require

- Terminal Type & Shape of heater

- Bushing or other option

- Application information including process temperature, Material being heated, corresive condition

- Effective Heating Length Required

- Drawing or photo if available

Construction Characteristics

PHC Tubular Heaters are the most versatile and widely used source of electric heat for industrial, commercial and scientific applications. They can be designed in a wide range of electrical ratings, diameters, lengths, terminations, and sheath materials. Important and useful characteristics of tubular heaters are that they can be formed into virtually any shape, brazed or welded to any metal surface, and cast into metals. Carefully researched manufacturing methods and quality materials have made PHC tubular heaters stand apart from other heating elements claiming similar performance.

We have hight standards and take pride in all we do

Typical Applications

- Forced air heating

- Thermal forming machines

- Direct immersion in liquids

- Comfort radiant heaters

- Welded, brazed or clamped to tanks and pipes

- Hot runner molds

- Combination

- radiant and convection heater for ovens and dryers

Watt Density

Element Watt Density is the wattage dissipated per square inch of the element sheath surface and is critical to the proper heating of the application and to the life expectancy of the heater. The Watt Density is calculated with the following formula:

- Many materials are heat sensitive and can decompose or be dam- aged if the element is running too

- Air and other gases that are poor conductors of heat require watt densities matched to the velocity of the gas flow to prevent element

- When heating hard water or cleaning solutions mineral deposits can build up on the element sheath, acting as a heat insulator and raising the internal element If these deposits cannot be periodically removed, use a lower watt density element to increase heater life expectancy.

Standard Tubular Heater Terminations

Select the termination style that meets your requirements for space, accessibility and reliability.

Note: If the listed terminations do not seem to fit your requirements, call us and let us design one that will.

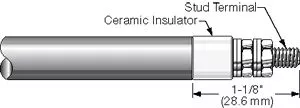

TYPE TS—STANDARD

Threaded stud terminal with ceramic insulator. Standard thread size is 6-32 for .260″ (6.6 mm), 8-32 for .315″ (8 mm), .335″ (8.5 mm) and .375″ (9.5 mm), and 10-32 for all other diameters. Other thread sizes and lengths are available as par Requirement.

TYPE TM

Type P – Plain Pin

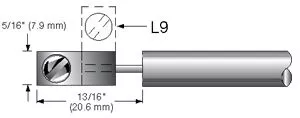

TYPE L1 TERMINATION– Screw lug terminal 90°.

Type L – Terminal Lug type.

TYPE D TERMINATION– Quick connect. Maximum 240V

TYPE D1 TERMINATION– Quick connect 90°. Maximum 240V

Type MR– Moisture resistant shrink strain relief and lead wire with or without stainless steel overbraid.

| Type | Insulation | Max. Temperature | Volts |

| WS | Silicone | 390°F (200°C) | 600V |

| WF | Fiberglass | 480°F (250°C) | 600V |

| WM | Mica/Glass | 840°F (450°C) | 600V |

Termination and Mounting Method

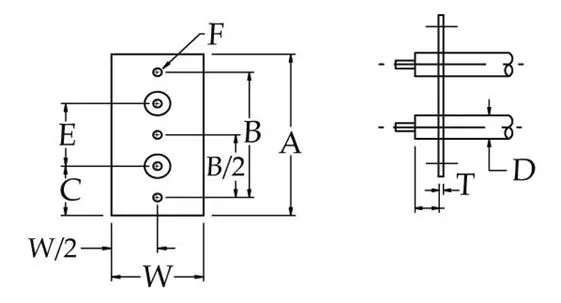

TYPE W MOUNTING– Locator washers

TYPE P MOUNTING-Mounting bracket

TYPE F MOUNTING– Threaded bulkhead fittings

TYPE F MOUNTING– Threaded bulkhead fittings

TYPE T MOUNTING– Threaded bulkhead fittings

Tubular Sheath & Watt Density Guidelines

| Heated Medium | Process Temperature °F (°C) | Sheath Material | Max. Watt Density W/in2 (W/cm2) |

| SOLIDS | |||

| Clamp on to Metal | To 500 (260) To 1000 (540) | Incoloy® | 20 (3) 10 (1.5) |

| Milled Groove Molds | To 500 (260) To 1000 (540) | Incoloy® | 60 (9) 30 (4.5) |

| Vacuum Platens | To 650 (345) To 1000 (540) | Aluminum, SS Incoloy® or Inconel® | 40 (6) 20 (3) |

| LIQUIDS | |||

| Clean Potable Water | To 212 (100) To 500 (260) | Copper Incoloy® | 60 – 90 (9 – 14) 30 – 40 (4.5 – 6) |

| De-I Water | To 212 (100) | 316SS | 60 (9) |

| Process Water & Very Diluted Corrosives | To 200 (95) | 304SS or Incoloy® | 48 (7.5) |

| Mild or Diluted Acids & Alkalies | To 200 (95) | Incoloy®, 316SS or Inconel® | 15–23 (2.3 – 3.5) |

| Oils (Depends on Type & Use) | 50 – 600 (10-315) | Steel | 6 – 23 (1 – 3.5) |

| AIR | |||

| Ovens, Natural Convection | To 700 (370) To 1200 (650) | Incoloy® | 30 (4.5) 10 (2.3) |

| Flowing Air @ Min. 500 fpm | To 800 (425) To 1000 (650) | Incoloy® | 30 (4.5) 23 (3.5) |

Maximum Recommended Sheath Temperatures

| Sheath Material | Maximum Temperature in Air °F (°C) | Typical Aplications |

| Standard Available Sheath Materials | ||

| Copper | 350 (175) | Clean, potable water heating |

| Aluminum | 750 (400) | Vacuum platens |

| Steel | 750 (400) | Oils, glycol, molten salts, non-corrosives |

| SS304 | 1200 (650) | Improved corrosion resistance over steel |

| SS316 | 1200 (650) | De-ionized water and some corrosives |

| Incoloy® 840 | 1600 (870) | Improved corrosion resistance over steel and 304SS |

| Incoloy® 800 | 1600 (870) | Improved resistance to chloride attack, other corrosives |

| Other Available Sheath Materials | ||

| SS321 | 1200 (650) | Improved corrosion resistance over steel and 304SS |

| Incoloy® 825 | 1600 (870) | Highly resistant to many acids, salts, and other media |

| Inconel® 600 | 1800 (980) | Highly resistant to many acids, salts, and other media |

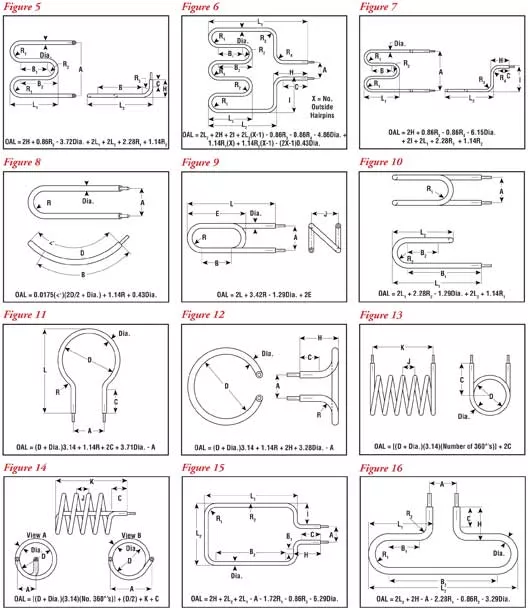

Typical Bandings

Patel Heaters & Control Pvt. Ltd.

Connect With Us Today!

Mobile

+91-987960 7852, +91-99258 22223/ 99789 16315

Address

901/5/5, Gidc, Makarpura Vadodara Gujarat India -390010

Landline no

+91-99258 22227,

+91-99258 22229

E mail

sales@patelheaters.com

Fill The Form To Connect With Us